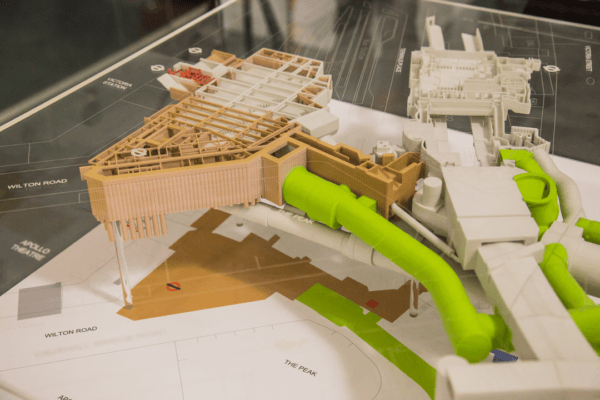

3D printing for a refurbishment project: TFL Underground Station

The refurbishment of Victoria Station Underground highlights 3D printing as a practical tool for communicating details of complex, multi-level structures

The Refurbishment Brief:

Transport for London (TFL) needed a way to convey refurbishment and upgrade plans for an underground tube station to a number of stakeholders, including various contractors, neighbours and local authorities. Above ground, the size of Victoria Station is only hinted at. Below ground complex systems of tunnels and rooms carry trains, utilities, employees and of course passengers. The different levels and sections are woven together intricately. This makes understanding the information on a 2D drawings challenging, especially for non-engineering stakeholders. An affordable and robust physical model was required to bring the plans to life and facilitate discussions.

Key Project Challenges:

- To communicate complex information to a wider audience

- Show relationship of elements within a multi-level structure

- Many connecting tunnels and structures

- Show location of structure relative to the constraints above and below ground

- Be robust enough to be used as a working model on-site

- 6 sections of models linking together

The Solution: 3D Printing for a refurbishment project

The existing station was 3D laser scanned, measuring millions of points of data, to create an incredibly accurate 3D model of the station layout. By linking the measurements together, the ‘point cloud’ data is used to re-create the physical space in a computer using specialist software. This was combined with the Victoria Station Upgrade works modelled in 3D.

This ‘BIM’ model was then scaled down to the size of the model required and prepared for 3D printing. Vibrant colours were chosen for the lines, ticket halls and other different sections to help them stand out in the finished model. The model was 3D printed on a powder machine, giving great colour and rigidity at an affordable price.

The 3D model was held in place above a technical drawing of the Scope of Works, printed at the same scale, using Perspex rods. The model was then placed into a Perspex case, which represents the ground level, so that the station entrance was above the level of the case. The case was also engraved with an outline of the surrounding buildings to show the location of the Project in relation to the neighbourhood of the station upgrade.

Victoria Station underground refurbishment 3D printed model

The Result

The Victoria Station Upgrade model is in constant use and located in the reception area on site and is a great example of 3D printing for a refurbishment project. The model has been very useful to ‘physically’ illustrate the Scope of the Project to Important dignitaries and stakeholders who regularly visit the Project Site Offices.

Other 3D printed models for other stations are already in the pipeline.

“Sharing the 3D design is just as essential as creating the design in the first place; the Project Team have been utilising 3D prints for several years. The overall 3D Print produced by Hobs… effectively communicates the extents of the Victoria Station Upgrade construction beneath the ground and conveys the challenges we are currently overcoming which people often fail to appreciate.” Paul Kick, Transport for London