Hobs 3D create virtual reality training system for Thames Tideway’s Tunnel Boring Machine

THE ORIGINS OF VRCUB3D:

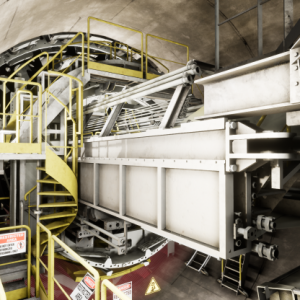

Over the last five years, there have been 35 fatal accidents and 217 construction related injuries documented in the UK. Thames Tideway, who are constructing a new tunnel in London to reduce the overflow of sewage into the River Thames, collaborated with Hobs 3D to develop an interactive, cost-effective virtual reality (VR) training system which would aid health and safety training for their Tunnel Boring Machine (TBM). The result of this unique project was Hobs 3D’s latest award-winning innovation, VRCUB3D.

With a fund of £5,500 from Ferrovial Agroman and Laing O’Rourke (FLO), Hobs 3D set out on producing a one-of-a-kind VR experience which would effectively provide training to protect the wellbeing of workers in the construction industry.

To realistically replicate the feeling of being inside a large underground tunnel, the team projected the TBM environment inside their pop-up VR system with the addition of multisensory features. Combining stereoscopic technology with the latest cutting-edge headsets gave construction workers a fully immersive experience, without having to put themselves in danger.

With only 17 interlocking pieces to hand, the VR system could be set-up easily and efficiently, saving valuable training time for staff. This also ensured it was compact enough to be moved to multiple training sites. As well as being easily transportable, VRCUB3D has various customisable options. Users can adjust the height, add logos and include multisensory features such as 4D sound, changing temperatures, smells and multiple screens, adding an extra level of immersion; ideal for environment simulation. The cube was also treated with a multi-layered protective coating and engineered to be water repellent, moisture resistant, and fire retardant.

Shay O’Carroll, National Sales Director at Hobs 3D commented: “The obvious focus at the moment is on training as well as health and safety, but we also have scope to start looking at controlling elements of TBM’s from the digital virtual environment, taking steps to use this as more than just a visualisation tool and instead starting to use it as a control centre. We’re also looking to the future of digital twinning, looking to interact with live environments.”

After creating success of the prototype, Hobs 3D took their VR system to ‘The Great Think’ Innovation Challenge – a Dragons’ Den style pitch, where market-leading companies exhibited how their innovations could improve health and safety, productivity and the environment. Hobs 3D were the only team to secure a full £20,000 investment from Thames Tideway and received an extra £67,500 from Innovate UK to further develop the concept.

Since the pitch, VRCUB3D has since gone from strength to strength, being exhibited at events across the country. With such advancements in the tech industry, Hobs 3D’s innovation proves that there is more potential for VR than ever before.